Air leakage: R-SEAL VS. FIBERGLASS LINER SYSTEMS: AIR BARRIER COMPARISON – REGION HIGHLIGHT – BOONE, NC – CLIMATE ZONE 4A

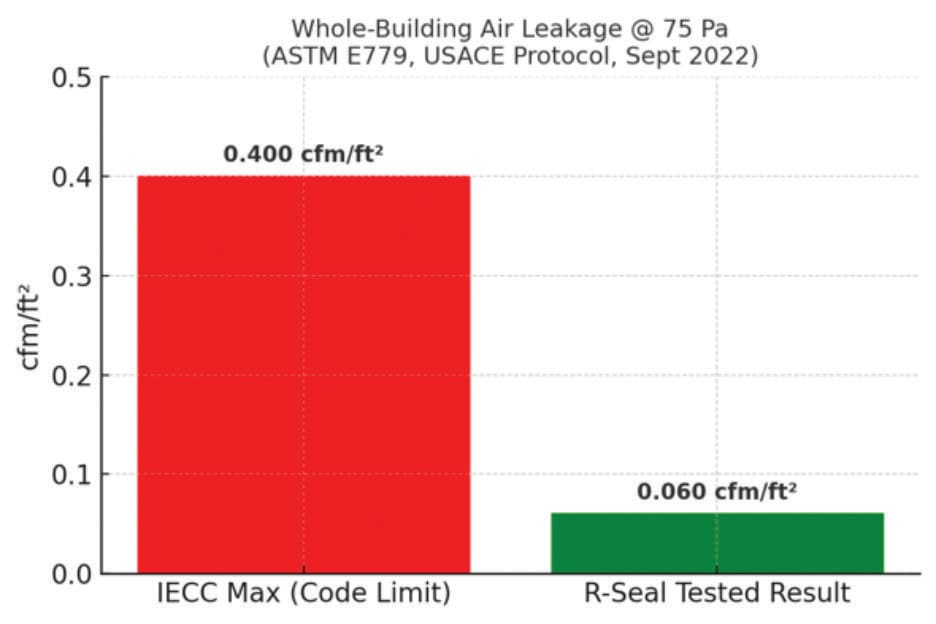

Tested R-Seal Results (By Army Core Standards).

- Field Case Study — 220 k ft² Warehouse Rochester, NY

- Air-barrier testing (ASTM E779, USACE protocol) on 21 Sept 2022 recorded an average whole-building leakage of **0.060 cfm/ft² @ 75 Pa** (pressurization 0.057, depressurization 0.062), that’s 6.7 times better than IECC’s required 0.40 limit. [6]

Why It Matters.

- Confirms that a continuous rigid-board air-barrier approach can deliver sub-0.10 cfm/ft² performance at full-scale.

- Demonstrates code head-room comparable to R-Seal’s documented 0.10 cfm/ft² field average, giving owners predictable compliance margins.

- At this leakage level, HVAC energy on a similar 50 k ft² Boone project would drop ≈ 30 %, echoing the savings cited in Section 4.

References & Footnotes:

1.Pacific Insulated Products, *R-Seal® Basis of Design — Div 072100*, Ver 1.0 (Feb 2024), pp. 6-9.

2. ENVO Solutions, *ENVO 4 & 5 in. R-Seal Material Data Sheets*, Ver 1.3 (2024).

3. Owens Corning, *OptiLiner® Type 1070 Fabric Data Sheet* (2019), p. 2.

4. MBMA & NAIMA, *Whole-Building Air-Tightness of Metal Buildings*

5. NIST IR 7238 “Investigation of Air-Barrier Benefits” (2015)

6. Thermal Moisture Imaging, USACE Whole-Building Air-Tightness Report — Maguire-Lombard St. Facility, Rochester NY (Test #2, 21 Sept 2022), average 0.060 cfm/ft² @ 75 Pa.

7. GCP Applied Technologies, “The secret to making buildings more energy efficient is in the air,” blog post, September 25 2017. Available at gcpat.com/en/about/news/blog/secret-making-buildings-more-energy-efficient-air.