2.6″ & 3″ R-Seal Rigid Envelope Insulation Panel

PRODUCT SPECS.

WIDTH COVERAGE

3′-5/3/4″ / 3.479′

THICKNESS

2.6″ & 3″

*STANDARD LENGTH

8′-0″ TO 53′-0″

EXTERIOR PROFILE

PS (Polypropylene/Scrim) Bonded to rigid foam

EXTERIOR FACE

Uniformed Dimpling Pattern

INTERIOR PROFILE

PS (Polypropylene/Scrim) Bonded to rigid foam

INTERIOR FACE

Uniformed Dimpling Pattern

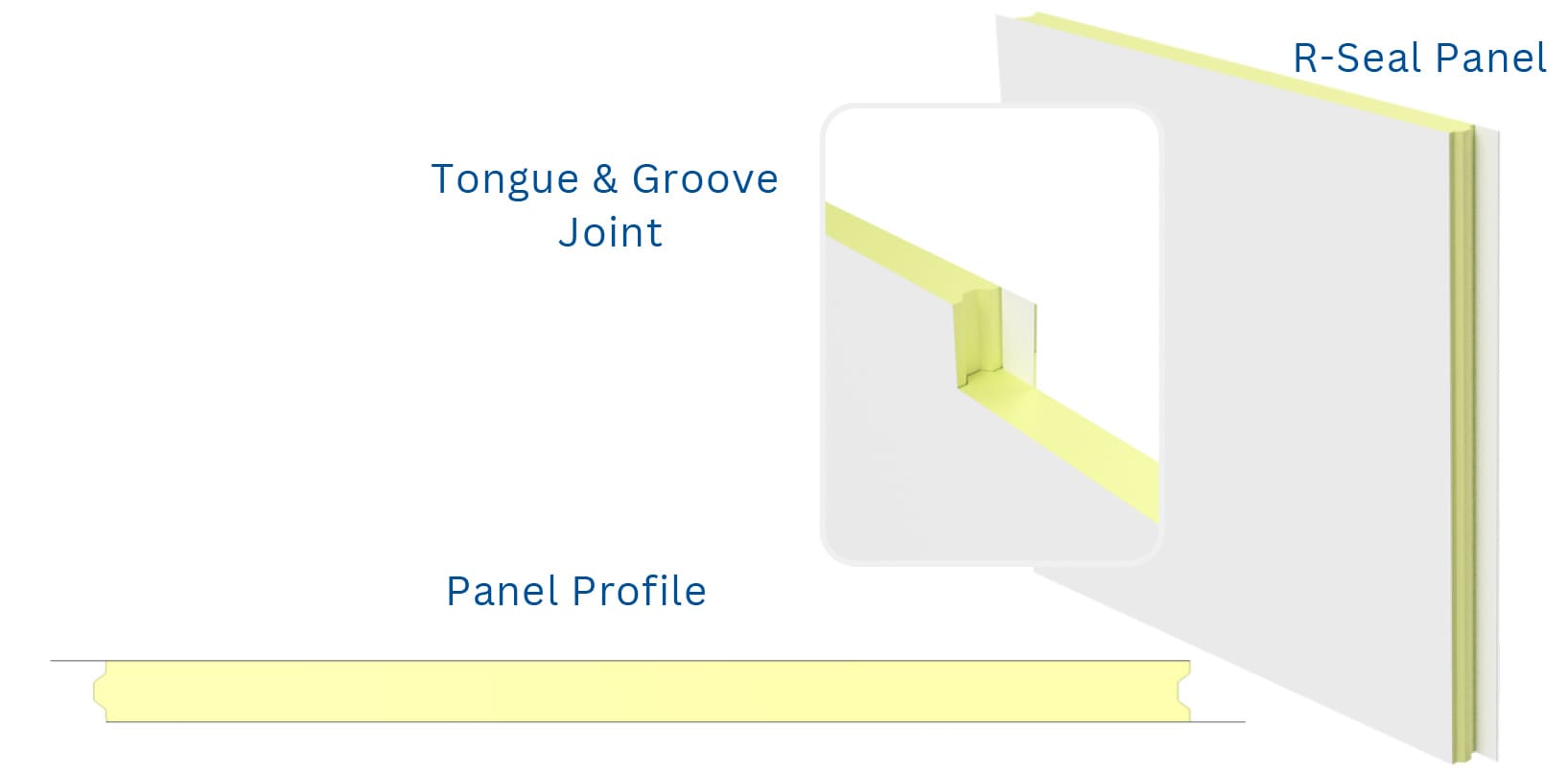

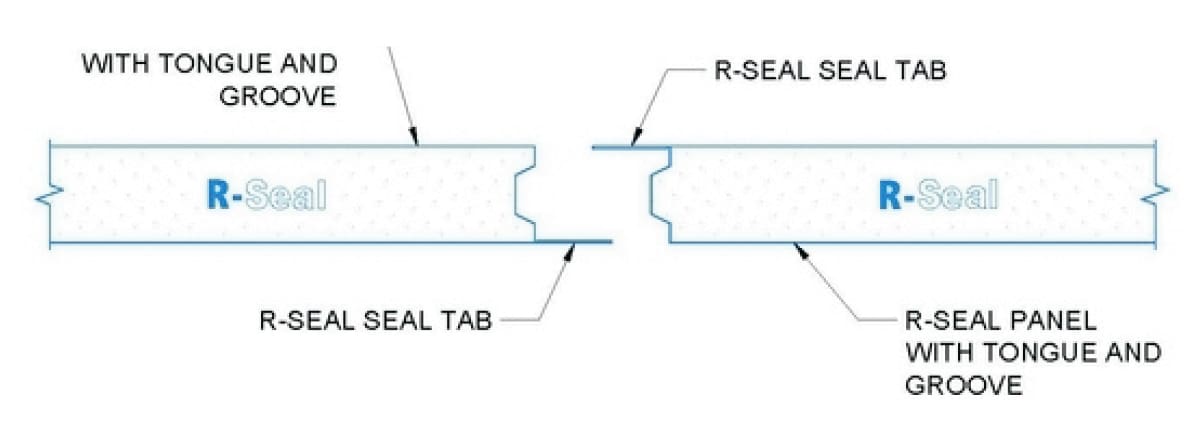

JOINT

Tongue & Groove

FASTENING

Through fastened with support channels at finished floor and eave areas

CORE

Rigid closed cell modified Polyurethane/PUR/PIR core, structural and fire-rated components between fiber-reinforced polypropylene.

*Custom Length Panels are Available Upon Request

R-SEAL TAPE TAB DETAIL.

R-VALUE AND U-FACTOR.

R-Value

U-Factor

Thickness/Inches

Joint Style

R-15

0.064

2.0″

Butt

R-20

0.050

2.6″

Tongue & Grooved

R-22.5

0.044

3.0″

Tongue & Grooved

R-30

0.031

4.0″

Ship Lap

R-37.5

0.027

5.0″

Ship Lap

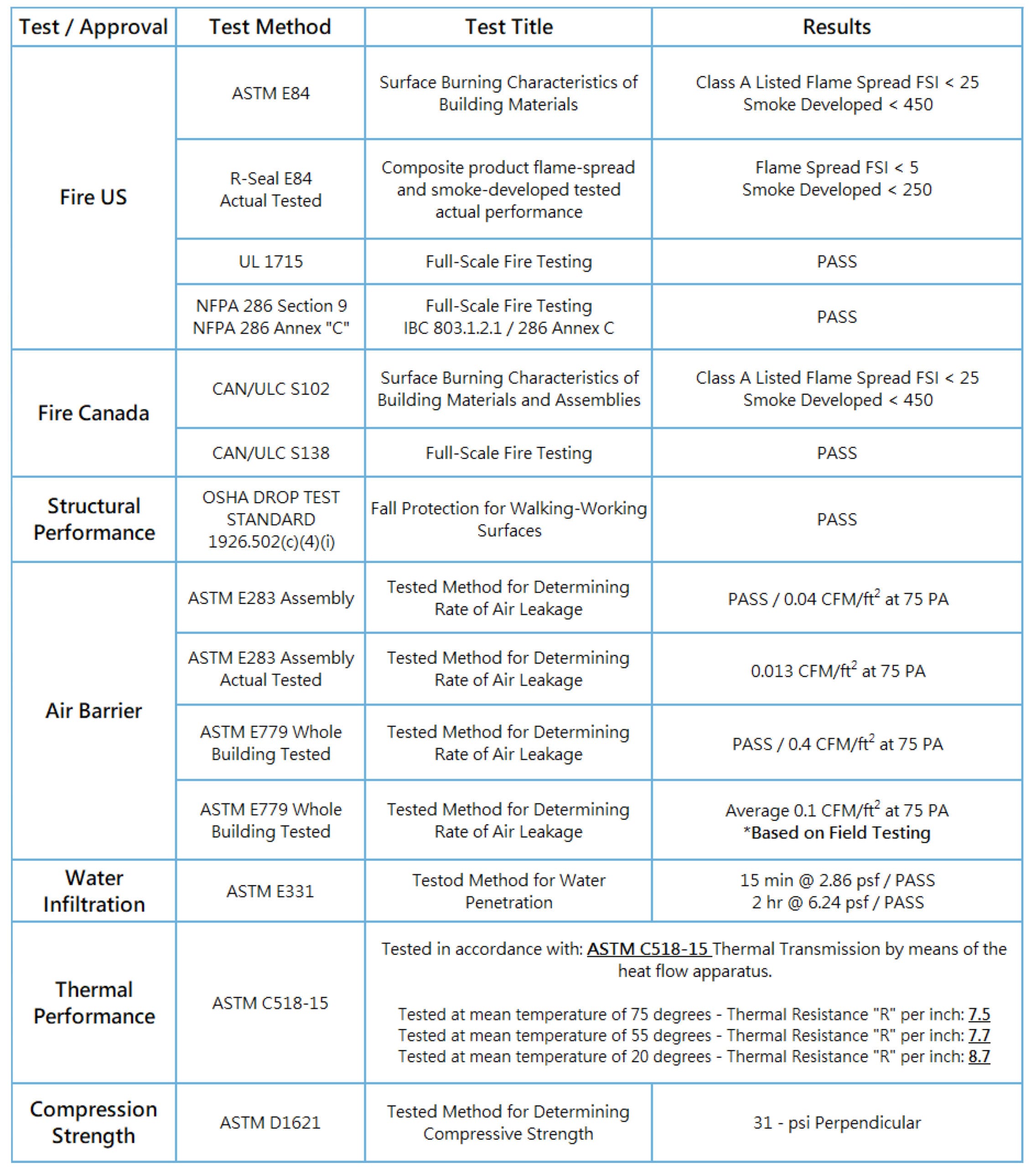

Test/Approval

Test Method

Test Title

Results

Fire US

ASTM E84

Surface Burning Characteristics of Building Materials

Class A Listed Flame Spread FSI < 25

Smoke Developed < 450

Fire US

R-Seal E84

Actual Tested

Composite product flame-spread and smoke-developed test acual performance

Flame Spread FSI < 5

Smoke Developed < 250

Fire US

UL 1715

Full-Scale Fire Testing

PASS

Fire US

NFPA 286 Section 9

NFPA 286 Annex "C"

Full-Scale Fire Testing

IBC 803.1.2.1 / 286 Annex C

PASS

Fire Canada

CAN/ULC S102

Surface Burning Characteristics of Building Materials and Assemblies

Class A Listed Flame Spread FSI < 25

Smoke Developed < 450

Fire Canada

CAN/ULC S138

Full-Scale Fire Testing

PASS

Structural Performance

OSHA DROP TEST STANDARD

1926.502(c)(4)(i)

Fall Protection for Walking-Working Surfaces

PASS

Air Barrier

ASTM e283 Assembly

Tested Method for Determining Rate of Air Leakage

PASS / 0.04 CFM/ft2 at 75 PA

Air Barrier

ASTM e283 Assembly Actual Tested

Tested Method for Determining Rate of Air Leakage

0.013 CFM/ft2 at 75 PA

Air Barrier

ASTM E779 Whole Building Tested

Tested Method for Determining Rate of Air Leakage

PASS / 0.4 CFM/ft2 at 75 PA

Air Barrier

ASTM E779 Whole Building Tested

Tested Method for Determining Rate of Air Leakage

Average 0.1 CFM/ft2 at 75 PA

*Based on field testing

Water Infiltration

ASTM E331

Tested Method for Water Penetration

15 min @ 2.86 psf / PASS

2 hr @ 6.24 psf / PASS

Thermal Performance

ASTM C518-15

Tested in Accordance with ASTM C518-15 Thermal Transmission by means of the heat flow apparatus

Tested at mean temperature of 75 degrees - Thermal Resistance "R" per inch: 7.5

Tested at mean temperature of 55 degrees - Thermal Resistance "R" per inch: 7.7

Tested at mean temperature of 20 degrees - Thermal Resistance "R" per inch: 8.7

Compression Strength

ASTM D1621

Tested Method for Determining Compressive Strength

31 - psi Perpendicular

Key Features & Benefits of the 3 Inch R-Seal Rigid Panel

The 3 inch R-Seal Panel delivers high-performance insulation that meets metal buildings’ practical and energy-efficiency needs across Ohio and the USA. Designed specifically for commercial buildings and pre-engineered structures, this panel provides unmatched benefits at the lowest installed cost.

- Superior Thermal Performance: With its closed-cell polyurethane core, the R-Seal panel offers excellent R-values for continuous insulation, reducing heat transfer and enhancing indoor comfort.

- Moisture and Air Barrier: The bonded PS facer resists water intrusion and acts as an effective air barrier, limiting air leakage and moisture damage.

- Rigid and Durable: Engineered to endure tough job site conditions, the panel maintains structural integrity and performs well over the long term.

- Code-Compliant: Designed to exceed requirements for insulation systems in Ohio and across the USA.

- Fast, Clean Install: The tongue-and-groove joints and custom lengths reduce the need for additional framing and cutting on-site.

Whether it’s a retrofit or a new build, the 3 inch R-Seal rigid panel supports faster construction timelines while meeting code compliance and energy efficiency goals.

Applications & Compatibility

The Perfect Fit for New Builds or Retrofits

The R-Seal Rigid Envelope Insulation Panel is highly versatile and optimized for various commercial and industrial settings. Ideal for:

- Metal Wall Systems

- Pre-Engineered Metal Buildings

- Industrial Warehouses

- Cold Storage Facilities

- Agricultural and Institutional Structures

Panels work seamlessly with typical wall panel systems used in metal construction and are designed to blend with standard layouts without added complexity.

Why Owners, Builders, & Erectors Trust ENVO Solutions

We deliver more than just insulation panels. Our 3 inch R-Seal panel system is engineered with features that simplify the building process and provide lasting value.

- Custom-Cut Lengths: Panels of up to 53 feet or longer are available to reduce waste and handling.

- Clean, Consistent Finish: Uniform dimpling pattern on both faces ensures aesthetic appeal without sacrificing performance.

- Time-Saving Integration: Eliminate time-consuming banding and fiberglass installs with our pre-engineered design.

- Support That Goes Further: From engineering documentation to on-site training and installation guidance, we help ensure your project stays on track.

Looking for more? Explore our full R Seal product line or learn more about the roof and wall insulation strategies we support.

Frequently Asked Questions

Q1: What’s the primary benefit of using the 3 inch R-Seal rigid panel?

A: It offers code-compliant continuous insulation, air/moisture resistance, and easy installation, making it ideal for industrial applications.

Q2: Can this panel be used in retrofit projects?

A: Yes. 3 inch R-Seal panels are suited for both new construction and retrofit insulation across a variety of commercial buildings.

Q3: Is the panel available in custom sizes?

A: Yes. Lengths range from 8’ to 53’+ depending on your building specs and project requirements in Ohio and the USA.

Q4: How does the 3 inch R-Seal envelope insulation panel speed up installation?

A: The panels feature tongue-and-groove joints and arrive in custom-cut lengths, allowing for quick, clean assembly without banding or additional sealing layers.

Q5: Is R-Seal safe and comfortable for crews to handle?

A: Yes. R-Seal panels are itch-free and lightweight, making them safer and easier to handle.

Simplify Your Next Industrial Project

Contact ENVO Solutions to learn how the 3 inch R-Seal Panel can deliver faster installs, better energy efficiency, and long-term value. We’re here to support your build from start to finish.